Fullt rörformiga nitar

As one of professional high quality Full Tubular Rivets manufacturer, you can rest assured to buy Full Tubular Rivets from Notin and we will offer you the best after-sale service and timely delivery.

Full tubular rivets are also called as hollow rivets or tubular rivets, they are a common mechanical fastener, primarily used in applications requiring lightweighting or ventilation. Their structural characteristics are a completely hollow center with heads at each end, achieving connection through plastic deformation. Widely used in electronics, automotive manufacturing, aerospace, and other fields, they are favored for their unique structural design.

What is a hollow rivet?

A full tubular rivet consists of a shank and a head. The shank has a through hole in the center, and the head is typically round or oval. During installation, the rivet is inserted through the materials to be joined, and the tail is expanded using a specialized tool to form another head, securing the materials together. Because of the hollow center, full tubular rivets maintain ventilation or fluid conduction after connection, which is their primary difference from solid rivets.

What materials can full tubular rivets be made of? What are the characteristics of different materials?

full tubular rivets are made from a variety of materials, with aluminum alloy, stainless steel, and copper being common.

Aluminum tubular rivets are lightweight and corrosion-resistant, making them suitable for electronic products and lightweight structures. They are the most cost-effective rivets.

Stainless steel tubular rivets are strong and heat-resistant, and are often used in automobiles and industrial equipment. They are more expensive than aluminum hollow rivets.

Brass tubular rivets or copper tubular rivets have good conductivity and are mostly used for electrical connections. Their disadvantage is that they are relatively expensive.

When selecting materials, factors such as the use environment, stress conditions, and cost should be considered.

Installation method of full tubular rivets

Special tools are required to install hollow rivets, such as manual riveting machines or fully automatic assembly machines.

The operation steps are as follows:

(1) Drill a hole in the material to be connected, with the hole diameter slightly larger than the rivet diameter.

(2) Insert the rivet into the hole, ensuring that the head is close to the surface of the material.

(3) Align the rivet hole with the matching punch (the punch is installed on the riveting machine). (4) Shake the riveting machine so that the tail of the rivet is impacted by external force and curls up, forming the same arc as the head, thereby achieving the fastening function.

Advantages of Full Tubular Rivets

(1) Light weight: The hollow structure reduces the amount of material used and is suitable for weight-sensitive applications.

(2) Good air permeability: The through hole in the middle can be used for ventilation or diversion to avoid sealing problems.

(3) Easy installation: Only one-side operation is required, which is suitable for narrow spaces or occasions where the back cannot be accessed.

(4) Low cost: Compared with welding or bolting, the riveting process is simple, saving time and manpower.

Disadvantages of Full Tubular Rivets

(1) Limited strength: The hollow structure leads to weak tensile and shear resistance, which is not suitable for high-load scenarios.

(2) Non-removable: Once installed, the rivet is usually not reusable, and disassembly will damage the connection.

(3) Requirements for material thickness: Materials that are too thin or too thick may affect the riveting effect.

What are the main applications of hollow rivets?

(1) Electronic products: such as computer cases, radiators, etc., taking advantage of their lightweight and air permeability.

(2) Automotive manufacturing: used for non-load-bearing parts such as interior panels and wiring harness fixings.

(3) Aerospace: reduce weight while meeting some ventilation needs.

(4) Furniture assembly: connect metal or plastic parts and simplify the installation process.

Comparison between hollow rivets and other rivets

(1) Compared with solid rivets: full tubular rivets are lighter and breathable, but have lower strength.

(2) Compared with semi-tubular rivets: the tail of semi-tubular rivets is partially hollow, with slightly higher strength, but the ventilation is not as good as full hollow rivets.

(3) Compared with blind rivets: the mandrel of blind rivets remains after installation, while the mandrel of full hollow rivets is completely detached, making the connection neater.

Suggestions for purchasing full tubular rivets

(1) Select rivets of appropriate length according to the thickness of the material to ensure that they can fully expand after installation.

(2) Consider the use environment. For example, corrosion-resistant or high-temperature resistant materials should be selected for humid or high-temperature conditions.

(3) Before purchasing in bulk, you can try it out first to confirm the riveting effect and tool compatibility.

Maintenance and precautions for full tubular rivets

(1) Avoid excessive force during installation to prevent rivet deformation or material damage.

(2) Regularly check the connection parts and replace them in time if they are loose or rusted.

(3) Keep them away from moisture during storage to prevent oxidation of the rivet surface that affects their use.

As a practical connector, full tubular rivets have irreplaceable advantages in specific scenarios. Understanding their characteristics and application methods will help you choose and use them reasonably in actual work, improving work efficiency and connection quality.

- View as

Tubular

Tubulära nitar består vanligtvis av en skaft och en mössa, med ett ihåligt centrum. Denna design tillåter slutet av skaftet att krulla utåt när den utsätts för axiellt tryck, och bildar en annan lockliknande struktur och därigenom klämmer fast två eller flera material. Till skillnad från bekanta fasta nitar kräver ihåliga nitar inte hammare från motsatt sida, vilket gör dem mer lämpliga för monteringsapplikationer som bara kan drivas från ena sidan.

Läs merSkicka förfråganStålrörsnitar

Stålrörsnitar erbjuder fördelar som lätthet, hög styrka, korrosionsbeständighet, utmärkt lufttäthet och hög tillförlitlighet. De är lämpliga för att förena olika material, såsom aluminiumlegeringar, stål och plast. Vidare minskar den ihåliga kroppen av stålrörsnitar avsevärt sin vikt och bidrar till den totala lättvikten av strukturen.

Läs merSkicka förfråganRostfritt rör med rostfritt stål

Rostfritt stålrörsnitar består av en kropp och en mössa, med en ihålig kanal däremellan. Denna design gör det möjligt för niten att säkra material genom att pressa eller expandera under sammanfogningsprocessen. Rostfritt stål valdes främst för dess korrosionsbeständighet. Kromen i rostfritt stål bildar en oxidfilm på ytan, förhindrar rost och förlänger nitens livslängd. Rostfritt stål erbjuder också utmärkt seghet och styrka, vilket gör det lämpligt för ett brett spektrum av miljöförhållanden. NUOT METALS är en tillverkare av rostfritt stålrör i Kina i mer än 10 år.

Läs merSkicka förfråganRörnitar

Rörnitar används vanligtvis i applikationer där fästning krävs men extrem styrka är inte. Till exempel i elektroniska enheter kan de användas för att ansluta kretskort eller bostadskomponenter. I tillverkning av möbler kan de användas för att fästa metall- eller träkonstruktioner. Vissa dekorativa föremål eller små mekaniska enheter använder också dessa nitar.

Läs merSkicka förfråganÖgonnitar

Ögonnitar är en mångsidig nit som vanligtvis används för att ansluta tunna aluminium- och stålplattor. De kännetecknas av vackra nitande punkter, stark struktur och justerbar höjd. De är lämpliga för att ansluta olika metallplattor och olika material. Ögonnitar kan vara varm-dip polerade för att bilda ett skyddande skikt på ytan, som har antistatiska, korrosionsbeständiga och anti-allergiska egenskaper.

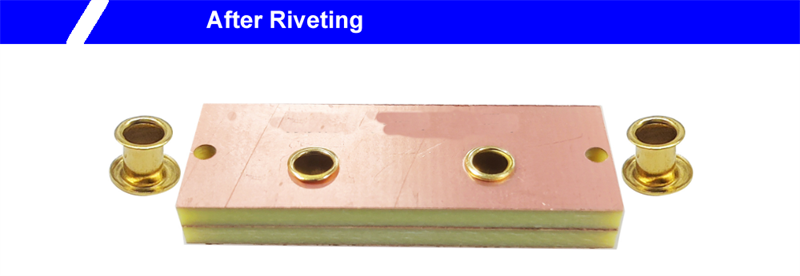

Läs merSkicka förfråganMässingsrörnitar

Mässingsrörsnitar är ett vanligt mekaniskt fästelement som används över ett brett spektrum av industrier. De är ihåliga cylindriska och har vanligtvis brims i varje ände. Mässingsrörsnitar uppnår en anslutning genom deformation och erbjuder utmärkt elektrisk konduktivitet, korrosionsbeständighet och enkel installation.

Läs merSkicka förfrågan